Textile Testing - Seam Slippage

Seam Slippage is one of four key topics (others include Abrasion Resistance, Pilling, and Colourfastness) that we are covering to provide some background as to how we test and why.

Test results provide us with critical information about textile’s durability and suitability for certain applications. We externally test all James Dunlop and Mokum textiles in Melbourne at a highly reputable laboratory who are amongst the most conservative and stringent in the world, due to the extremely harsh environmental conditions we face here in Australia and New Zealand.

We have gathered a number of frequently asked questions relating to seam slippage, so we asked our Mokum Studio designers Stephanie Moffitt and Annie Moir to share their expert knowledge.

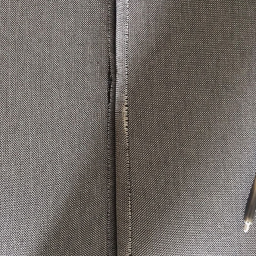

Seam slippage is another equally important upholstery test, can you explain what seam slippage actually means?

Seam slippage is the separation or pulling apart of yarns in a fabric usually along a sewn seam or join. More often than not, the yarns don’t actually break they just separate and leave an unsightly gap along the fabric join.

What are the most common causes for seam slippage?

Seam slippage may be the result of a poorly constructed textile and /or the use of defective yarns in the fabric. But more commonly it is due to an inadequate standard of upholstery manufacturing i.e. a display of insufficient seam allowance, a deficient number of stitches in the seam or failure to overlock raw edges during the upholstery process – or a combination of all three factors.

Seam slippage usually occurs on joins that are subjected to heavy load and pressure such as seat cushions and arm rests. Certain furniture styles put more stress on fabric seams such as tub chairs and furniture with a fixed back or seat cushions.

Can composition play a part in seam slippage?

Yes, it can, Linen for example is loved for being a smooth lustrous fibre, but this can make it more susceptible to seam slippage with heavy load. For some linen textiles we would recommend discussing the need for reinforcing upholstery seams with your upholstery manufacturer.

The note “reinforce upholstery seams” is sometimes listed on our sampling specifications – what does it actually mean? Should we assume the fabric is inferior quality?

Firstly, no it doesn’t infer inferior quality. If we’ve specified it as being suitable for upholstery then it is fit for purpose, but we recommend additional seam support for that particular textile.

“Reinforce upholstery seams” simply means using an additional safeguard by stitching a tape along the seam to prevent fraying in high load areas, such as the corner back cushions. Overlocking should be used for loose woven fabric and seated cushion seams.

What’s the remedy for seam slippage? Can you fix it once it starts?

It is difficult to repair seam slippage once it starts. In almost all instances of seam slippage, it will require the furniture to be recovered, or re upholstered. It’s important to ascertain the cause of the seam slippage. If the seam slippage can be identified as being a result of inadequate manufacturing, you’ll need to work with the upholsterer to ensure appropriate manufacturing techniques are being used, including reinforcing seams if required. If the seam slippage is clearly related to the fabric, the furniture would need to be recovered, either from a different batch (if it’s an isolated batch issue) or selecting an alternative fabric which is more suitable for that particular frame.

Can you explain how the seam slippage test is performed?

The test measures how resistant a fabric is to yarns opening/ slipping under pressure along a seam line. Two fabric swatches are sewn together with a standardised seam. The swatches are pulled apart with an equal and opposite force. The test is performed in both warp and weft directions. Any seam opening is then measured while the fabric swatches are being pulled apart. According to the Australian standard, a seam opening should be less than 6mm at maximum force. A lower result indicates a smaller opening and thus a better resistance against seam slippage.

Written by: jamesdunloptextiles.com...

Neighbourhood Challenge: Who Can Crack This One? ⛓️💥❔

What has a head but no brain?

Do you think you know the answer? Simply 'Like' this post if you know the answer and the big reveal will be posted in the comments at 2pm on the day!

Want to stop seeing these in your newsfeed?

Head here and hover on the Following button on the top right of the page (and it will show Unfollow) and then click it. If it is giving you the option to Follow, then you've successfully unfollowed the Riddles page.

Tacking the bamboo-like pest in the Manawatū

🌱 A new national scheme led by Biosecurity New Zealand is tackling an invasive weed that’s threatening wetlands, waterways, and forests in and around Manawatū, reports the Manawatū Standard.

💬 Our question to you: Do we sometimes overlook plants when investing in conservation?

Have you spotted this weed in your area, or noticed other local efforts to protect our native flora?

Some Choice News!

Many New Zealand gardens aren’t seeing as many monarch butterflies fluttering around their swan plants and flower beds these days — the hungry Asian paper wasp has been taking its toll.

Thanks to people like Alan Baldick, who’s made it his mission to protect the monarch, his neighbours still get to enjoy these beautiful butterflies in their own backyards.

Thinking about planting something to invite more butterflies, bees, and birds into your garden?

Thanks for your mahi, Alan! We hope this brings a smile!

Loading…

Loading…